TLDR:

- Hooi Tan, President of Global Operations and Supply Chain at electronic manufacturer Flex, discusses the transformational impact of advanced technologies on the manufacturing industry.

- Three key elements of advanced manufacturing have emerged: real-time decision making, real-time modifications, and smart factory lines.

Artificial Intelligence (AI) is a breakthrough technology that has the potential to transform the way we live and work. In the manufacturing industry, there are three key elements that define the next era of manufacturing: real-time decision making, real-time modifications, and smart factory lines.

Machine connectivity is a crucial aspect of advanced manufacturing. It involves collecting data from machines, people, and processes, and using AI models to make real-time decisions and optimize operations. Machine connectivity functions like a nervous system, transmitting data from different parts of a manufacturing ecosystem.

Making real-time decisions allows for reduced downtime and optimization of operations. The frequency of decisions and the key performance indicators (KPIs) used can vary depending on the specific manufacturing process. By tracking and adjusting in real-time, manufacturers can prevent unplanned downtime and save substantial costs.

Real-time modification is another crucial element of advanced manufacturing. Technologies like IIoT and AI/ML can be deployed to eliminate bottlenecks in the manufacturing process and improve efficiency. AI and video can be used to improve the quality inspection process and reduce scrap.

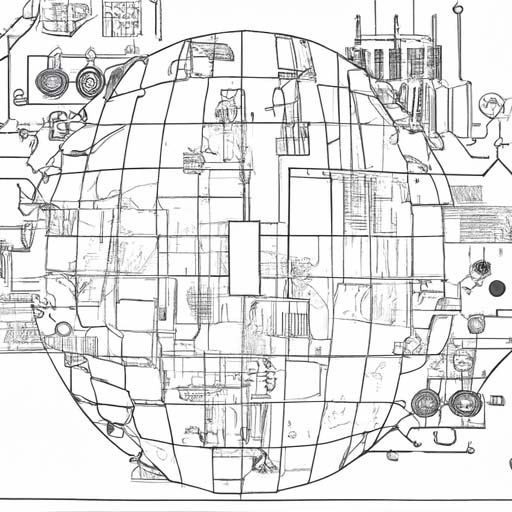

Smart factory lines combine machine connectivity, AI/ML, and other transformative technologies to optimize the manufacturing process. By using sensors to detect defects in real-time, the production line can be stopped, recalibrated, and continued once the issue is resolved. This leads to smarter, more efficient, and sustainable manufacturing over time.

To fully leverage the benefits of advanced technologies like AI, companies must consider the bigger picture, learn from mistakes, and apply learnings across the entire manufacturing ecosystem. Standardizing vendors and usage and involving all stakeholders like IT for data and security are essential for successful implementation.

In conclusion, advanced technologies such as AI are transforming the manufacturing industry by enabling real-time decision making, real-time modifications, and the development of smart factory lines. These technologies have the potential to optimize operations, reduce downtime, improve quality, and empower human workers to handle more complex tasks.