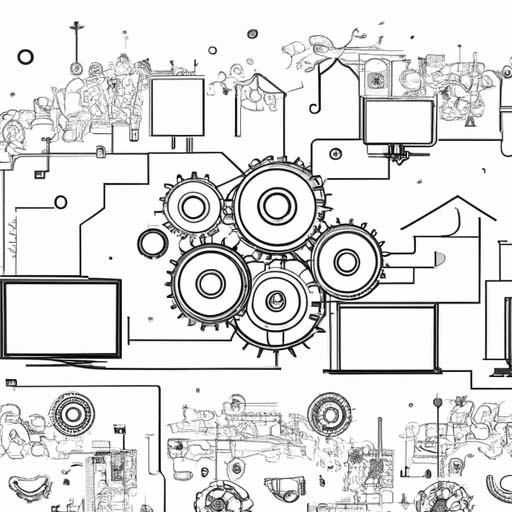

The number of new warehouses being built in North America and Europe declined by 25% during 2023, contributing to increased caution among warehouse operators. In addition, the rapid growth of e-commerce has led to a shortage of suitable warehousing space in urban and suburban areas, prompting operators to consider alternatives to greenfield development. One option is to increase the density of their pick operations by installing mezzanines and pick towers within existing facilities. These vertical enhancements can double or triple the amount of warehousing space that can be used, but they also increase the complexity of fulfillment operations. Automation, including autonomous robotics, can help to maximize the potential of vertical enhancements by increasing productivity and throughput. Advanced automation solutions need to incorporate software and hardware features specific to vertical and high-density locations, such as warehouse navigational systems that can distinguish between different levels and understand product location. Additionally, automation solutions need to be data-centric, incorporating data analytics and predictive and artificial intelligence to optimize tasking. Furthermore, the physical attributes of the facilities and robots need to be considered, such as the size, weight, and maneuverability of the robots. Implementing automation in greenfield projects can enhance picking efficiency by 15% to 20%. Robots offer flexible automation solutions that can be scaled up or down according to business needs, which is particularly important in uncertainty times. Overall, going vertical and combining it with automation can significantly increase picking density and improve warehouse efficiency.