Key Points:

- The article discusses the importance of continuous improvement in manufacturing operations.

- It highlights the benefits of implementing lean manufacturing principles and automation technology.

The manufacturing industry is constantly evolving, with companies striving to improve their operations and increase efficiency. One crucial aspect of successful manufacturing is continuous improvement, which involves constantly analyzing and refining processes to eliminate waste and optimize productivity. In this article, we will explore the key elements of continuous improvement in manufacturing and discuss the benefits of implementing lean manufacturing principles and automation technology.

Lean manufacturing:

One of the most popular methodologies for continuous improvement in manufacturing is lean manufacturing. It is based on the idea of minimizing waste and maximizing value. By identifying and eliminating non-value-added activities, companies can streamline their processes, reduce costs, and improve overall productivity. Lean manufacturing focuses on eliminating the seven types of waste, including overproduction, waiting time, unnecessary processing, excess inventory, unnecessary movement, defects, and underutilized employees.

In addition to waste elimination, lean manufacturing also emphasizes the importance of teamwork and employee involvement. It encourages cross-functional collaboration and empowers employees to identify and implement process improvements. This not only enhances employee engagement but also leads to more effective and sustainable improvements in manufacturing operations.

Automation technology:

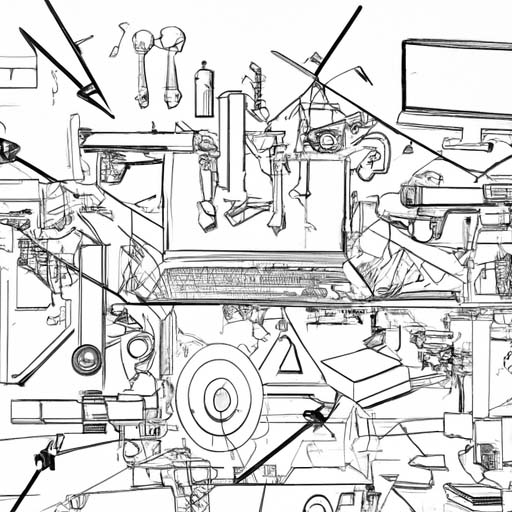

In recent years, automation technology has become an essential tool for continuous improvement in manufacturing. Automation can help streamline processes, reduce errors, and increase productivity. By automating repetitive and time-consuming tasks, companies can free up their employees’ time to focus on more valuable activities.

Automation technologies like robotics, artificial intelligence, and machine learning enable manufacturers to achieve higher levels of efficiency and precision. They can perform tasks with consistent accuracy and reliability, reducing the risk of errors and defects. Additionally, automation technology can collect and analyze data in real-time, providing valuable insights for process optimization.

Implementing automation technology may require significant upfront investment, but the long-term benefits are substantial. It can enhance productivity, reduce costs, improve product quality, and enable companies to stay competitive in a rapidly changing market.

Conclusion:

Continuous improvement is a fundamental aspect of successful manufacturing operations. By implementing lean manufacturing principles and leveraging automation technology, companies can streamline their processes, reduce costs, and improve productivity. Emphasizing waste elimination, teamwork, and employee involvement, lean manufacturing enables sustainable improvements in manufacturing operations. Automation technology further enhances efficiency, reduces errors, and provides valuable insights for process optimization. To stay competitive in today’s dynamic manufacturing landscape, companies must embrace continuous improvement and invest in lean manufacturing and automation.